Rapidplastics comprises the entire production chainfrom

project design and

project design and

mold making, through

mold making, through

moulding of the final item, till

moulding of the final item, till

product assembly and

product assembly and

delivery logistics.

delivery logistics.

Object design↥ go up

Rapidplastics assists its clients in all of the initial steps of the development process. The profound technical knowledge of the materials, their properties and potential process problematics allows us to offer the best process rout for the making of the product. Proud of our pluri-decennial knowledge of all productive processes, our object design assistance includes the usage of modern software for 3-D modeling and mold flow simulations. On client demand we are able to provide in brief time prototypes using materials similar to those used for the production.

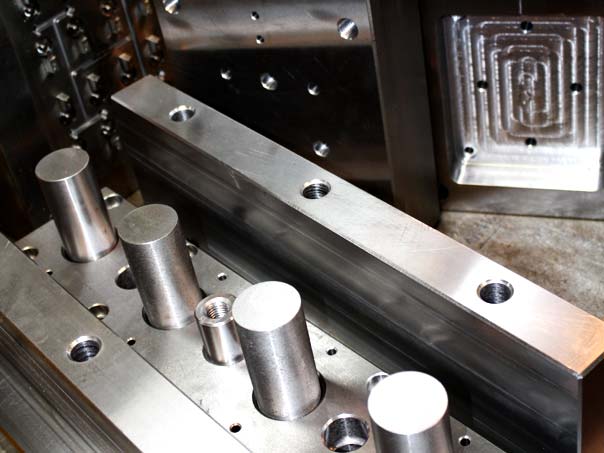

Mold Making↥ go up

Within Rapidplatic’s walls there is an internal mechanical shop equipped with electroerosion devises and rectification machines as well as a CNC milling cutter and a lathe. Our operational office and our machinery shop integrate each other allowing to produce optimized molds in brief time. The machine shop guarantees operation autonomy and seasonableness for any production or maintenance request. Special care is taken in mold storage. Molds are kept inside a conditioned chamber where regular inspections assure mold’s promptness for use at any time.

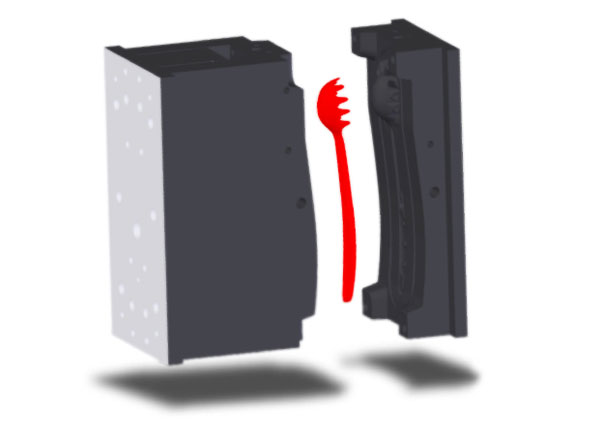

Injection Molding↥ go up

Rapidplastics is specialized in the injection mold of all plastic materials: thermoplastic, thermosetting, elastomers and silicones.

The production shop is equipped with the following:

- 45 presses from 500KN to 13000KN for thermoplastic mold injection;

- 4 presses for the injection mold of thermosetting materials;

All of the machinery listed above is automatized and robotized as well as equipped with a centralized unit for material supply. The material management is entrusted to a monitoring computer that is in constant contact with the presses. Such control allows to optimize at any moment the process parameters. Computer software and microprocessors within each press guarantees optimal repetitiveness of all process parameters.

Part Assembly and Finishing↥ go up

Upon work completion Rapidplastics possesses various internal shops for part assembly and finishing processes.

As in today, we are able to performs the following:

- Drilling;

- Welding;

- Serigraphy and pad printing;

- Superficial finishing such as galvanic treatments and painting;

- Assembly;

- Packaging;

The great flexibility that characterizes Rapidplastics allows us to offer personalized production lines even at the finishing stages of the production process.

Product Delivery by Own Means↥ go up

The entire warehouse is managed by modern software that allows to rationalize and accelerate packaging stages and just-in-time product deliveries. Transportation is provided using own means and company’s personnel which allows us to guarantee faultless products delivered and abidance to all delivery agreements and deadlines.